Even though the technology has advanced there is no beat to the little house spider. The spider silk threads have got the engineers surprised due to its huge energy absorption power without breakage. It is stronger than steel and also springier than rubber too.

The scientists have created synthetic silk threads which have similar properties as the normal spider counterparts. Earlier, synthetic fibers have been produced in the goat milk and silk proteins called “spidroins” have been produced in the bacteria, yeast and insect cells. These have been used to form scaffolding for the developing brain cells. Since the spiders produce a small amount of thread, there is a need for recombinant spidroins production in order to generate synthetic spider silk threads.

The earlier generated spidroins weren’t the exact replicas of the original ones; therefore, they clumped up, were produced in low quantity at low concentration or remained insoluble in the liquids. Also, they lacked luster and physical properties if they weren’t treated extensively.

According to the scientists, the spiders produce the fibers in the silk-spinning ducts. The ducts have a pH in the range 7.6 to 5.7. The change in the pH causes the protein to assemble in a lock-and-trigger pattern, which is then pushed through a duct with a force that causes the fibers to form strands. The different spiders had different pH range and solubility.

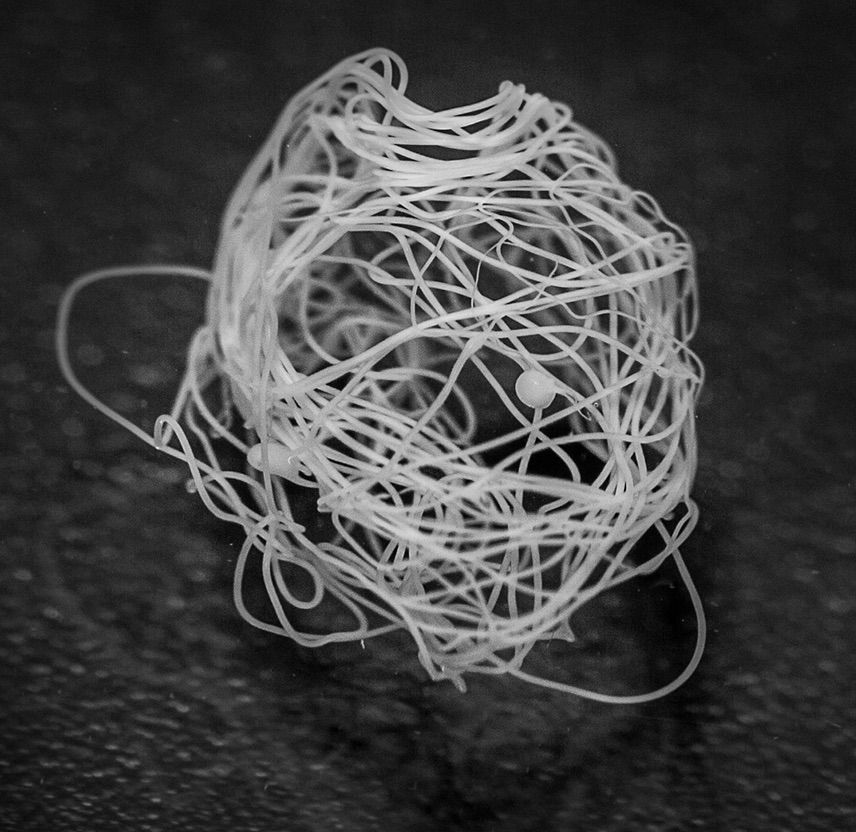

Hence, the researchers were doubtful about whether mimicking the spider glands is possible. The researchers produced a hybrid spider silk gene called “NT2RepCT” combining spidroin genes of two different spiders. The hybrid gene had the amazing properties such as high solubility and sensitivity to pH. The gene was inserted into a bacterial DNA where the proteins were produced. The protein solution produced was highly concentrated, cloudy and viscous similar to the spider protein in its glands. The solution was then forced out of a thin glass capillary that mimicked the shearing in a spider for fiber formation. The synthetic silk threads produced were 3,280 feet in a 0.26-gallon flask. The NT2RepCT fibers had elastic or toughness behavior similar to spider silk until a yielding point. After which its properties decreased and resulted in breakage.

Thus, the scientists are still finding out new means of its production.